One of the biggest myths of Industry 4.0 is that you need to start from scratch. For many manufacturing leaders, the vision of a "smart factory" seems to require a massive, budget-breaking overhaul of every machine on the floor. But what about the reliable, decades-old equipment that still forms the backbone of your production line? Replacing it is often financially unfeasible and operationally disruptive.

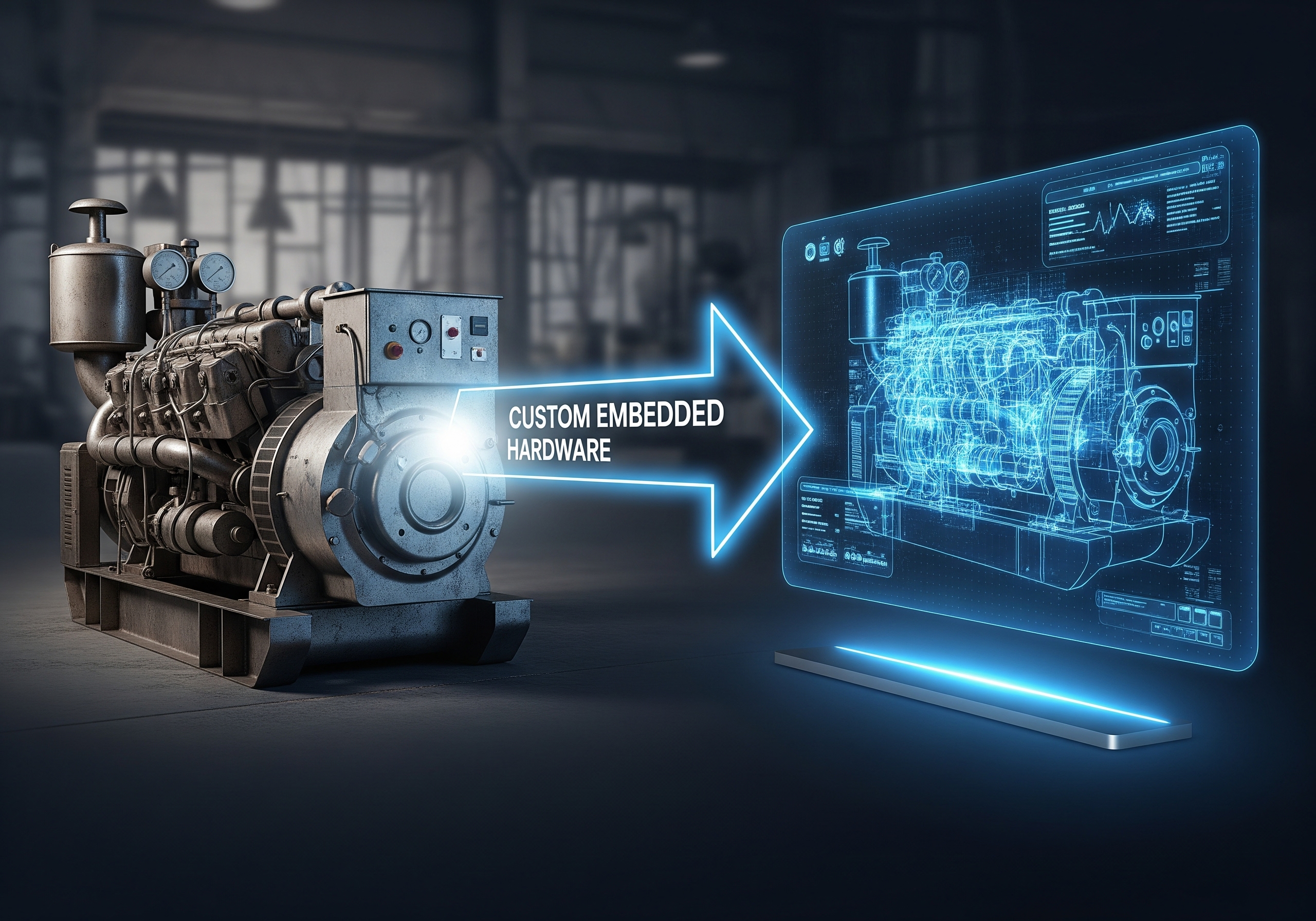

The good news is, you don't have to. It is entirely possible to bring your "dumb" machines into a smart, connected ecosystem. The key lies in **custom embedded hardware**—a core capability we specialize in at CBNsense.

The Challenge: Trapped Data

Legacy machines, while mechanically sound, are often "black boxes." They do their job, but they don't communicate. They don't share their operational status, their performance metrics, or early warning signs of failure. This trapped data is a goldmine of operational intelligence that you're unable to access.

The Solution: Custom Embedded Hardware

Instead of replacing the entire machine, we build a dedicated hardware solution to act as its brain and voice. This is not an off-the-shelf product; it's a bespoke solution designed specifically for your equipment and your needs.

How It Works:

- Sensor Integration: We start by identifying the key performance indicators (KPIs) you need to track. This could be temperature, vibration, cycle time, or output volume. We then integrate the necessary modern sensors directly onto your legacy equipment to capture this data.

- Custom Hardware Development: At CBNsense, we have the in-house capability to design and build dedicated embedded hardware. This device acts as a mini-computer that reads the data from the new sensors, processes it at the edge, and translates it into a standard digital format.

- Seamless Connectivity: Our hardware is designed to communicate wirelessly with our central AI/IIoT platform, sending a continuous stream of data from your newly intelligent machine.

The CBNsense Advantage: We Build What You Need

Many integrators can connect modern systems, but very few have the deep hardware expertise to build a bridge to your legacy equipment. Our ability to design and manufacture custom embedded solutions is what sets us apart. We don't force you into a one-size-fits-all solution; we build the exact hardware required to solve your specific problem, ensuring that no machine is left behind in your digital transformation journey.

The Result: A Truly Unified Factory

By retrofitting your legacy equipment with custom intelligence, you can achieve the benefits of Industry 4.0 at a fraction of the cost of a full replacement. You gain complete visibility into your operations, unlock the power of predictive maintenance, and integrate every piece of your factory floor into a single, powerful, data-driven ecosystem.