AI & Industrial IoT

IT/OT Convergence: The Key to Unlocking True Smart Factory Potential in India

The promise of Industry 4.0—smart factories, predictive analytics, and hyper-efficient operations—is a major focus for the Indian manufacturing sector. Yet, many companies find their progress stalled by a fundamental, decades-old challenge: the deep divide between Information Technology (IT) and Operational Technology (OT).

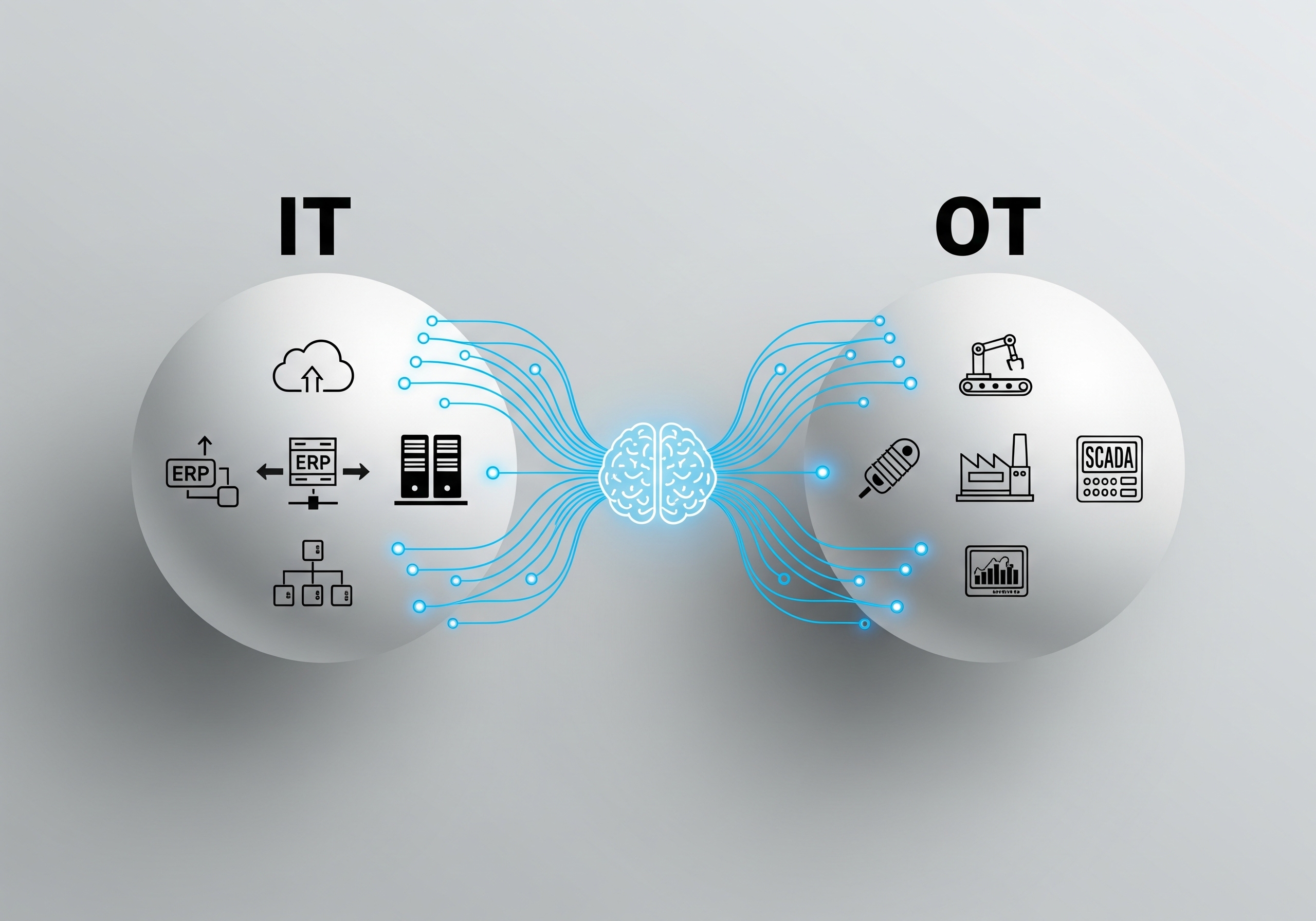

IT is the world of business systems: ERPs, CRMs, cloud servers, and data analytics. OT is the world of the factory floor: machinery, SCADA systems, sensors, and industrial controls. Historically, these two worlds have operated in complete isolation. IT speaks the language of data packets and APIs, while OT speaks the language of PLCs and industrial protocols.

This separation is the single biggest hurdle to achieving true operational intelligence. You can't have a "smart factory" if your smartest systems can't talk to your factory. **This is where IT/OT convergence comes in.**

What is IT/OT Convergence?

IT/OT convergence is the process of integrating your IT systems with your OT systems to create a single, unified data ecosystem. It means breaking down the silos so that real-time data from your machinery can flow seamlessly into your business analytics platforms, and insights from your business platforms can be used to optimize operations on the factory floor.

The Benefits of a Unified Data Strategy

For Indian manufacturing companies, the benefits are transformative:

- Complete Visibility: Gain a real-time, "single pane of glass" view of your entire operation, from supply chain logistics in your ERP to the performance of a specific machine on the production line.

- Data-Driven Decision Making: Move beyond gut feelings and historical reports. Make strategic decisions based on live, accurate data from the heart of your operations.

- Predictive Maintenance: By analyzing data from your OT systems, our AI/IIoT platform can predict equipment failures before they happen, drastically reducing costly downtime and extending the life of your assets.

- Improved Efficiency (OEE): Identify hidden bottlenecks, optimize production schedules, and improve your Overall Equipment Effectiveness (OEE) by understanding the true performance of your machinery.

How CBNsense Makes It Happen

True IT/OT convergence is more than just connecting a few wires. It requires deep expertise in both worlds. At CBNsense, we specialize in bridging this gap.

1. Deep System Integration

We are experts in integrating with all your existing systems, whether it's a modern cloud-based ERP or a legacy SCADA system. We understand the complex protocols and data formats of both IT and OT environments.

2. Legacy Modernization

What about your older, non-digital machinery? We design and install custom embedded hardware solutions that bring your legacy equipment into the 21st century, allowing them to communicate and share data with your modern systems.

3. A Powerful AI/IIoT Platform

Once the data is flowing, our platform is where the magic happens. It cleans, contextualizes, and analyzes the unified data stream to deliver the actionable insights and predictive alerts that power your smart factory.

The Future is Converged

For Indian manufacturing to compete on a global scale, embracing Industry 4.0 is not an option; it's a necessity. The journey begins with breaking down the walls between your factory floor and your front office. By unifying your IT and OT systems, you can unlock a new level of intelligence and efficiency that will drive your business forward.