AI & Industrial IoT

Predictive Maintenance vs. Preventive Maintenance: What's the Real ROI?

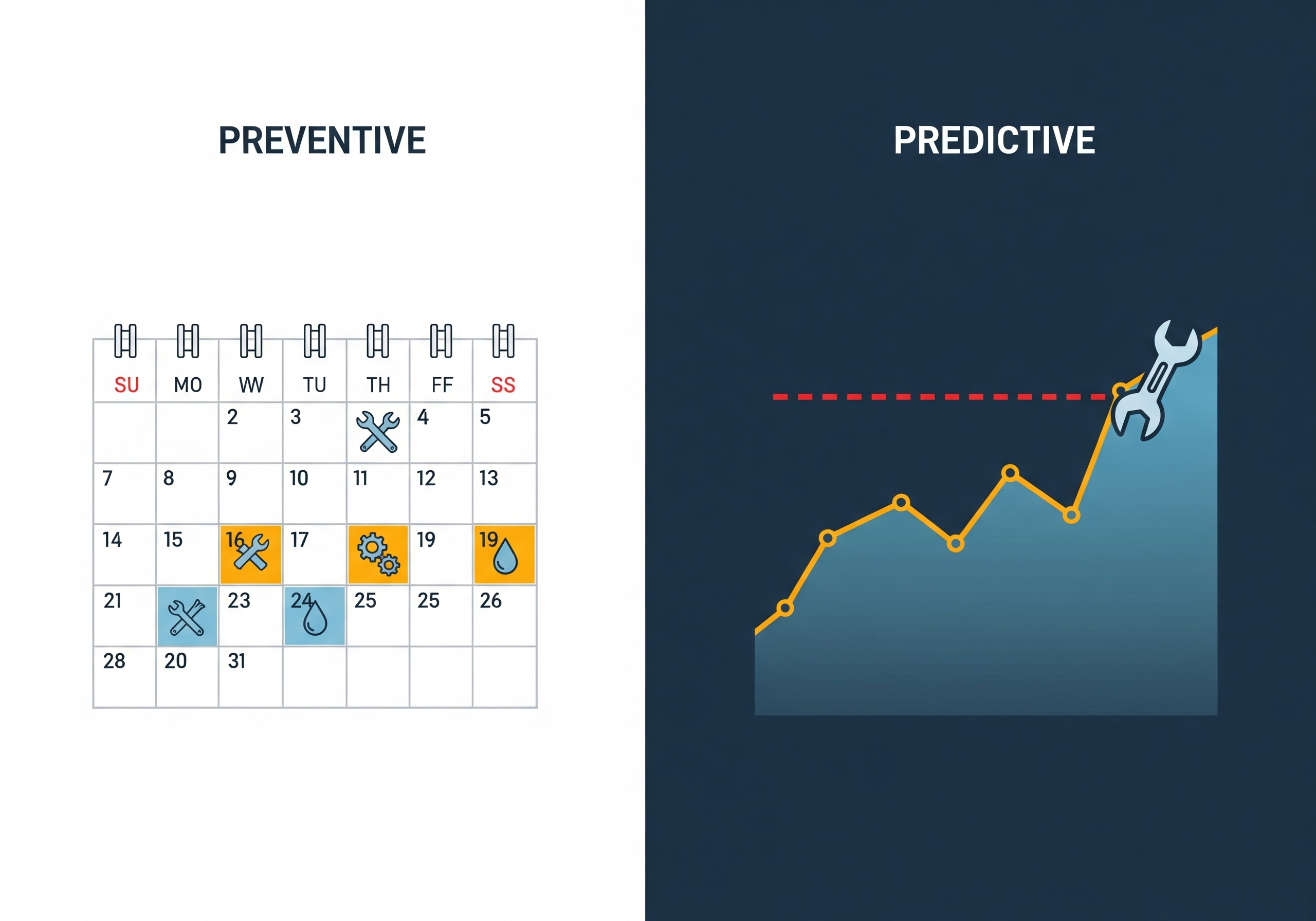

For decades, the gold standard in industrial maintenance has been **preventive maintenance**: servicing equipment on a fixed schedule, regardless of its actual condition. It's a reliable strategy that has served manufacturers well, but it has a fundamental flaw—it's incredibly inefficient. You either service machines too often, wasting time and resources, or not often enough, risking catastrophic failure.

The advent of Industry 4.0 and the Industrial Internet of Things (IIoT) has unlocked a far superior approach: **predictive maintenance (PdM)**. By using real-time data and AI, PdM allows you to service equipment at the exact moment it's needed, maximizing uptime and minimizing costs.

Understanding the Difference

Preventive Maintenance: The "Check-Up" Model

This is a time-based approach. You change the oil in your car every 10,000 kilometers, whether it needs it or not. In a factory, this means stopping a production line to service a machine every 500 hours of operation. It's a safe but wasteful strategy.

- Pro: Reduces the likelihood of unexpected failures.

- Con: Leads to unnecessary maintenance, wasted staff hours, and premature replacement of perfectly good parts.

Predictive Maintenance: The "On-Demand" Model

This is a condition-based approach. Instead of relying on a schedule, you use IoT sensors to continuously monitor the health of your equipment. Our AI platform analyzes data on vibration, temperature, and performance to detect subtle anomalies that are invisible to the human eye. It then alerts you to a potential failure *before* it happens, allowing you to schedule maintenance at the optimal time.

- Pro: Eliminates unnecessary maintenance, maximizes the lifespan of parts, and drastically reduces unplanned downtime.

- Con: Requires an initial investment in sensor technology and an AI/IIoT platform.

The Real ROI of Predictive Maintenance

The return on investment from switching to a predictive model is multi-faceted:

- Reduced Maintenance Costs: Studies have shown that predictive maintenance can reduce maintenance costs by up to 30% by eliminating unnecessary servicing.

- Drastically Reduced Downtime: Unplanned downtime is the single biggest cost for most manufacturers. PdM can reduce or even eliminate it, leading to massive gains in productivity.

- Increased Asset Lifespan: By servicing equipment only when needed, you extend the life of your machinery and get more value from your capital investments.

- Improved Safety: Predicting failures before they happen can prevent catastrophic events that could endanger your workers.

Making the Switch with CBNsense

At CBNsense, our AI/IIoT platform is the engine that powers a successful predictive maintenance strategy. We integrate sensors with your equipment, collect and analyze the data in real-time, and provide you with clear, actionable alerts. We help you move from a schedule of "just-in-case" maintenance to a data-driven strategy of "just-in-time" intervention.